Fluorescence-free radiant flux measurement of UV LEDs

Content:

Introduction

Developments in UV LED technology continue to raise the quantum efficiency of devices as well as improve their package design. This has resulted in steadily increasing radiant flux and reliability whilst costs decrease thereby allowing UV LEDs to replace conventional UV sources in many applications. Of particular note is the performance and lifetime now achieved by UV-C LEDs which enables new application areas including water purification in domestic products and air purification systems for example, as well as replacing deuterium lamps in spectroscopic instrumentation such as HPLC equipment. Therefore, the accurate and traceable measurement of UV LEDs has become increasingly necessary. In addition to the measurement of spectral irradiance, the measurement of spectral radiant flux is fundamentally important. Typically, either an integrating sphere or a goniometer based system is used for the measurement of radiant flux. Integrating sphere measurements are generally preferred, particularly for product testing and binning, as they are significantly faster and the facility is usually more cost-attractive.

Measurement challenges

However, UV measurements encounter more challenges than similar visible light tasks due to a number of issues including detector sensitivity, calibration and fluorescence. Available measurement devices typically possess a lower spectral responsivity in the UV than in the visible region which reduces their signal-to-noise, especially in the UV-B and UV-C, during calibration and subsequent measurements.

Only a small selection of calibrations lamps is available compared to those available for the visible region. Furthermore, the available calibration sources (typically deuterium lamps) provide lower signal levels and are not as stable as the widely used halogen lamps most commonly used for visible light calibrations. It should also be mentioned that the calibration source aging is generally much more pronounced in the UV compared to the visible spectral region. As a result, the calibration of UV spectroradiometer equipment can be quite complex requiring the combination of deuterium and halogen lamps.

Finally, fluorescence is a challenge in the UV that is not usually relevant or considered when measuring visible light. It can result in severe errors in UV measurements if it is not properly understood and appropriately dealt with. Many materials tend to exhibit some UV excited fluorescence, even with low levels of UV irradiation, which can falsify measurement results. This is the case for the common integrating sphere coating materials barium sulfate and ODM (a synthetic coating). Additionally, any material contaminants and surface pollutants will increase the fluorescence of the integrating sphere materials. Due to the fundamental principle of integrating spheres (multiple reflections to achieve constant irradiance level in the sphere; gain factor due to high reflectivity), fluorescence is especially important for these measurements (and calibrations).

This article discusses the more suitable sphere material as well as its peculiarities in order to be able to perform spectral radiant flux measurements with the lowest possible measurement uncertainty over an extended period of time.

Fluorescence

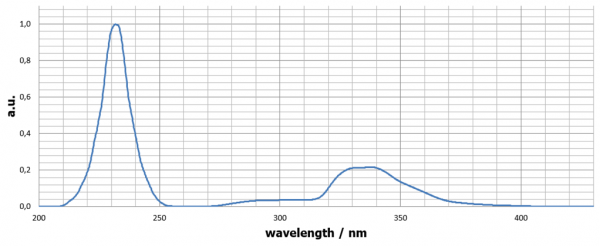

In order to determine the magnitude of any fluorescence affects within an integrating sphere it is convenient to use a tuneable laser (e.g. OPO) to measure the fluorescence resulting from different excitation wavelengths (see Figure 1). With such a tuneable laser different excitation wavelengths in the UV can be produced and coupled into the integrating sphere under investigation. The resulting signal, including any fluorescence affect, can be measured with an appropriate spectroradiometer measurement system so long as the stray light rejection of the measurement system is sufficient.

Figure 1:Measurement of an ODM and a barium sulfate coated integrating sphere with 230 nm excitation wavelength. The signal that can be seen between 280 nm and 400 nm is caused by fluorescence in the integrating sphere.

The additional signal shown in Figure 1 (between 280 nm and 400 nm) is caused by the fluorescence of the sphere itself and is a measurement error. A stray light corrected spectroradiometer with stray light level of lower than 1E-5 was used for this measurement. Furthermore, part of the actual measurement signal must be absorbed at 230 nm in order to produce this fluorescence. The fluorescence signal of 1E-2 shown arises from just a single monochromatic excitation wavelength. Measuring a 230 nm LED with a given FWHM bandwidth, for example, would stimulate fluorescence throughout the entire spectral range of the LED and the fluorescence contribution would be significantly greater. Therefore, fluorescence is clearly a significant contribution to measurement uncertainty for such measurements and can easily be in the order of 20% (depending on the spectral distribution of the light source and the integrating sphere used). See example in Figure 2 for an ODM (synthetic material) sphere measurement of a 230 nm LED:

Figure 2: Fluorescence resulting from a simulated 230 nm LED in an ODM sphere can easily be in the region of 20%.

The dominant cause of fluorescence lies in contaminants such as hydrocarbons and other organic material which forms on or penetrates the surface of the sphere coating [3, 6]. It is usually only excited at wavelengths below 250 nm. Therefore, for measurements at wavelengths >250 nm the effect of fluorescence is less critical, as long as fluorescence effects are also considered during calibration. This is the case for instance if an integrating sphere is calibrated with a halogen lamp (significant signal only >250 nm) and measurements are performed >250 nm. However, this changes if the calibration is performed with either a deuterium or xenon lamp as they both produce significant output below 250 nm which would result in some fluorescence affects thereby increasing the calibration uncertainty.

Barium sulfate or ODM?

The measurement data from Figure 1 shows that the fluorescence of an untreated ODM sphere is fundamentally higher than that of a barium sulfate sphere. However, what matters is the magnitude of the remaining fluorescence after a special treatment of the sphere coating. Measurements show that the fluorescence properties of ODM can be reduced but not completely eliminated. This is in line with the publication in LED Professional (October 2018, Issue 63 Link [1]), where the fluorescence of ODM-like material was reduced from 0.9% to only 0.05% at one excitation wavelength. Although the fluorescence was reduced, it could not be completely avoided. Consequently, this still results in a measurement error. For the aforementioned UV LED this would still be an additional measurement error in the range of about 1%. PTB has also published a paper confirming this [4, 5]. In contrast, the fluorescence of integrating spheres with a particularly well-prepared barium sulfate coating can be reduced even further than that of ODM, see Figure 3:

Figure 3: Fluorescence at 300 nm reduced by a factor of 28 for a pure barium sulfate coated sphere after ageing.

The fluorescence at 300 nm, for example, could be reduced by a factor of 28. For the aforementioned UV LED measurement, this means a much smaller measurement error of just 0.1%. For this reason, the PTB is again using UV-aged barium sulphate coated spheres in the UV for this type of measurement [2].

In the end it is an trade-off what is more important. The fluorescence is lower for barium sulfate, but the long term spectral reflectivity performance of ODM is better in the deep UV. Especially when deep UV radiation of higher power is measured. Since the ODM fluorescence can be reduced significantly but needs to be done regular a system combining a aging lamp might be ideal suited.

Recurrence of fluorescence?

Another uncertainty is the temporal stability of these spheres. In other words, does the fluorescence return? The answer is very clear, yes. The rate at which it does return depends on contamination by pollutants such as hydrocarbons and other gases as well as the influence of humidity on both coating types (ODM or barium sulphate) [3]. Therefore, the return of fluorescent affects is dependent on the prevailing ambient measurement and storage conditions. However, in all cases the fluorescence returns over a certain time frame, see for example Figure 4:

Figure 4: Recurrent fluorescence measured at 325 nm resulting from different excitation wavelengths. Lowest signal occurs immediately after treatment.

Therefore, a regular re-aging of the system is essential to ensure fluorescence-free measurements.

Metrological solution

In order to be able to implement this measurement technology, a UV spectral flux measuring system has been developed that incorporates an integrating sphere with a specially pre-treated barium sulfate or ODM coating. In addition, an effective system should include a treatment lamp along with the necessary application protocol that allows the user to keep the system fluorescence-free. Figure 5 shows such a measurement system.

Figure 5: Gigahertz-Optik TFUV10 measurement system for permanent fluorescence-free measurements

The measurement system enables long-term fluorescence measurements from 200 nm to 550 nm at 1 nm optical bandwidth and ~ 0.16 nm / pixel resolution. In addition, different 2-Pi calibration lamps (deuterium and halogen) are available for the measurement system in order to calibrate the entire spectral range. Of particular importance is the 2-Pi geometry of the calibration lamps, which makes it possible to achieve low measurement uncertainties for UV LED measurements because the measurement geometry during calibration is very similar to the geometry during the subsequent LED measurements. Of course, the calibration sources should be calibrated by an accredited laboratory with traceability to an NMI like PTB or NIST.

Conclusion

Fluorescence is a significant contribution to measurement uncertainty when the radiant flux of UV sources that emit at wavelengths less than 250 nm is measured using integrating spheres. Fluorescence can easily increase the uncertainty in the range of 20% when using conventional integrating spheres for specific UV measurements. This issue is becoming more and more important due to the increasing number of UV LED applications and range of products incorporating deep UV LEDs. In order to permanently reduce the measurement uncertainty, special treatment methods are required in addition to a suitable integrating sphere coating material and production processes. Measurements show that barium sulphate offers lower fluorescence than synthetic coatings like ODM. Although ODM has the advantage of higher reflection properties especially in the deep UV and better UV stability under high UV power radiation. For sources emitting only at wavelengths greater than 250 nm ODM generally remains a very good choice due to its increased reflectance compared to barium sulfate. Since the fluorescence after the special pre-treatment slowly but steadily increases with time, the concept of an ongoing-treatment is also necessary for this application. With the described TFUV10-V01 measuring system, a complete metrological solution is offered that takes into account all aspects of this topic (with resulting fluorescence less than 0.1%) providing the user with long term accuracy. The customer can choose between the both coating materials and we are happy to assist in order to select the best suited solution.

References

[1] LED Professional, Oktober 2018, Issue 63 Link

[2] Gesprächsnotiz Peter Sperfeld, PTB

[3] Shitomi H., Saito I., Photoluminescence from White Reference Materials for Spectral Diffuse Reflectance upon Exposure to the Radiation Shorter than 400 nm, Newrad 2005

[4] Pape S., Sperfeld P., Barton B., Stock K., Analyses and reduction of fluorescence on PTFE-coated integrating spheres, https://www.ptb.de/cms/ptb/fachabteilungen/abt4/jahresbericht-aktuelles/nachricht-aus-dem-jahresbericht.html?tx_news_pi1%5Bnews%5D=748&tx_news_pi1%5Bcontroller%5D=News&tx_news_pi1%5Baction%5D=detail&tx_news_pi1%5Bday%5D=1&tx_news_pi1%5Bmonth%5D=10&tx_news_pi1%5Byear%5D=2010&cHash=e2cf784ed439321f83cabeba493669f3

[5] Albert E. Stiegman, Carol J. Bruegge, Arthur W. Springsteen, "Ultraviolet stability and contamination analysis of Spectralon diffuse reflectance material," Opt. Eng. 32(4) (1 April 1993)

[6] Shaw P.S., Li Z., Arp U., Lykke R. K., Ultraviolet characterization of integrating spheres, Applied Optics, 2007