Conformity assessments at Gigahertz Optik GmbH

The accuracy and, above all, the traceability of measuring devices play an increasingly important role. Numerous standards and guidelines from various industries (e.g. automotive industry, medical industry) require the regular monitoring and calibration of measuring devices, measuring systems, complex systems and measuring processes in accordance with common standards such as ISO 17025. As a result, there are some new terms in circulation whose specific meaning is not always clearly understood, e.g. the difference between an ISO 17025 calibration laboratory and an ISO 17025 test laboratory . The need for a ‘declarations of conformity’ is also becoming increasingly important in industry. For the user in particular, these declarations of conformity can offer a decisive advantage and increased confidence. We at Gigahertz Optik GmbH, with our extensive calibration laboratory and thus our special position in the market, also have the highest demands in this regard. In the following we try to concisely explain the subject of declarations of conformity with reference to calibrations.

According to the definition in the ISO / IEC 17000 standard, a conformity assessment or declaration of conformity is a "statement that specified requirements relating to a product, a process, a system, a person or a body have been fulfilled".

In addition to a test or calibration, the conformity assessment enables a customer / user to obtain further certainty as to whether a device is still OK and which permissible limit values / parameters were complied with or exceeded at the time of the test. Therefore, a conformity assessment means benefit for customers in industry, research and other sectors. One of the best-known examples in Europe is the CE mark, in which the manufacturer guarantees the conformity of a device in accordance with the applicable regulations.

In order to be able to carry out a conformity assessment, the service provider and customer must agree on the assessment criteria and decision-making rules or these must be precisely defined in a standard (e.g. DIN EN ISO / IEC 17025: 2017 Sections 7.1.3 and 7.8.6). The evaluation criteria often relate to selected specifications that are specified by the manufacturer. However, individual criteria can also be set if, for example, specifications are not known or deviating values are to be used.

This can also be applied to calibrations and/or tests. Usually one of the following two decision rules is used, which is determined on the basis of the deviation of the measured values from a nominal value:

1. Decision rule under consideration of the measurement uncertainty

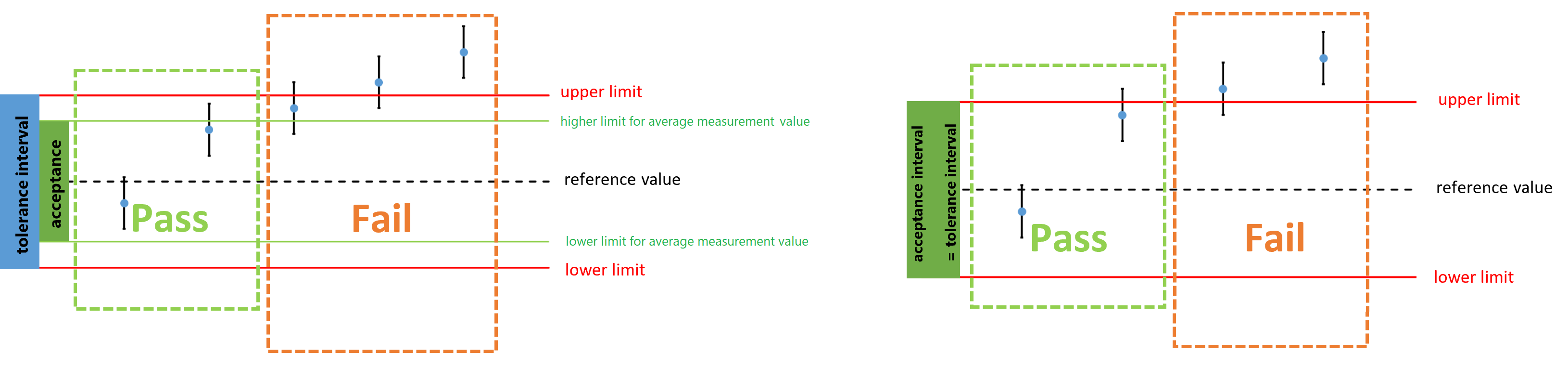

Here, the tolerance interval as well as the acceptance interval must be considered under consideration of the measurement uncertainty, see e.g. CIE S025 section 4.1.2 ; Fig. 1 and Fig. 2). In light metrology, k=2 and thus the minimum probability of 95% are common.

2. Decision rule without measurement uncertainty

Therefore, the simpler decision rule without consideration of the measurement uncertainty is often used. In this case, the probability is 50% in the worst case.

In both cases a binary decision is made (measured value is either within (pass) or outside (fail) the defined limits). This is graphically illustrated in the following two figures.

Fig. 1 (left): decision rule under consideration of the measurement uncertainty, Fig.2 (right): decision rule without measurement uncertainty

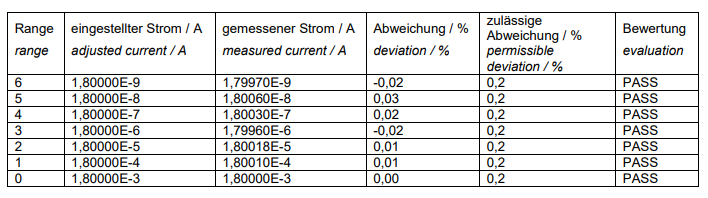

For further illustration, we show below a simple example of a conformity assessment of a current meter. Here, the conformity assessment is the verification of specific points of the individual amplifier stages with an allowed tolerance range of maximum 0.2% specified by the customer. I.e. in this case the measured values may only deviate from the nominal value of the current source by a maximum of 0.2%. It was jointly determined that the measurement uncertainty (which is considerably lower than the permissible deviation/decision criterion) should be disregarded, i.e. assessed in accordance with the decision rule from Fig.2:

Fig. 3 Example of a conformity assessment

At the request of customers the DAkkS-accredited calibration laboratory of Gigahertz Optik GmbH offers calibrations with a declaration of conformity about the described standard decision rules according to ILAC-G8:09/2019. The criteria for conformity and the decision-making rule must be precisely defined together.

Please do not hesitate to contact us if this topic is of interest to you. We'll work with you to decide upon the best solution.

References:

- Conformity assessment - Terms and general principles (ISO / IEC 17000: 2020); Trilingual version EN ISO / IEC 17000: 2020

- CIE S 025: 2015 - Test method for LED lamps, LED lights and LED modules

- DIN EN ISO / IEC 17025: 2018-03 - General requirements for the competence of testing and calibration laboratories (ISO / IEC 17025: 2017); German and English version EN ISO / IEC 17025: 2017

- ILAC-G8:09/2019: Guidelines On Decision Rules and Statements of Conformity