This product is no longer manufactured. Remaining stock may still be available. Please refer to the alternatives listed below under "Similar products" or contact us directly.

Alternative Products for this discontinued product:

DCP LED Test Station

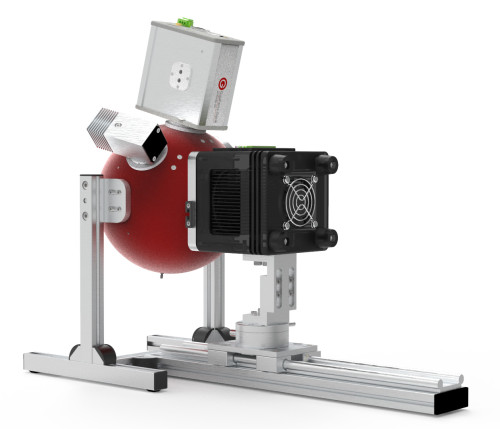

Spectroradiometer based DCP LED Test Station for Radiant Power of UV LEDs

- DCP Method of IES LM-92 and currently ongoing CIE TC2-91 work for high precision UV LED measurements.

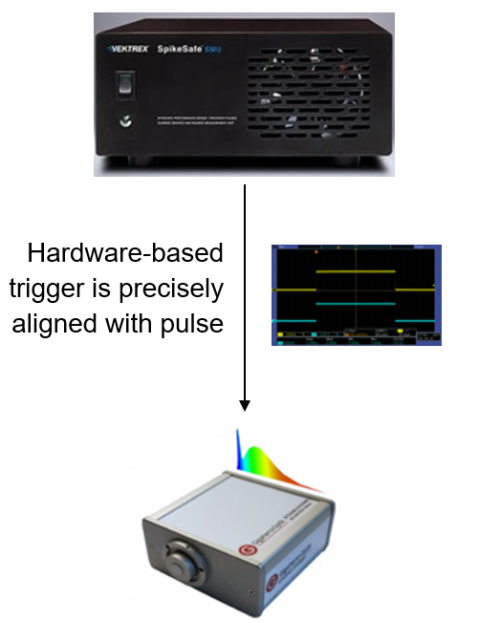

- VektrexTM SMU implemented for precise current settings for short pulses and sweeps.

- DCP Method implemented in application software, or as Python tool (SMU and spectroradiometer).

- 150 mm fluorescence-free integrating sphere and spectroradiometer with low stray light, ODM coating.

- Optional calibration standard for system recalibration by the user.

Peculiarity when measuring UVC LEDs

A peculiarity of quasi monochromatic LED radiation must be considered when designing integrating sphere spectroradiometers for UV LEDs. The monochromatic UV radiation of the LED causes fluorescence of the integrating sphere coating which leads to significant measurement errors that cannot be compensated by conventional correction methods. This system is based on the know-how of our fluorescence-free TVUV10 UV LED measurement system.

See also our technical article Fluorescence-free radiant flux measurement of UV LEDs.

DCP Method Requirements and Solution

For accurate measurements with the DCP method (IES LM-92-22 and ongoing work in CIE TC2-91) two requirements need to be met:

- A fast (µs range) spectroradiometer which is optimized for UV measurements

- A fast (µs pulses) SMU

If this is not ensured the measurement uncertainty raises since temperature effects or jitter produce larger errors.

Together with VektrexTM we set-up a UV LED Test station for accurate and fast DCP method measurements. The current is sweeped automatically within the desired range and the full scan can be done within seconds to minutes. Either run with a Python script or in the S-BTS2048 application software.

Integrating sphere for radiant flux measurement

A standard configuration of the spectroradiometer’s entrance optic for total radiant flux measurement is a 100 mm diameter integrating sphere with an input aperture of 25.4 mm diameter. However, other designs are of course possible due to the design options of our integration sphere construction kit.

High resolution spectroradiometer

The BTS2048-UV is part of the BTS2048 Series that has proven itself in a wide variety of demanding applications ranging from high-speed LED binning to NMI grade measurements. Such applications require the highest precision as well as reliability for continuous use. The spectroradiometer that is attached directly to the integrating sphere without using a light guide offers a spectral range from 250 nm to 430 nm with a spectral resolution of 1 nm. Remote-controlled optical filters increase the dynamic range. The pixels of the temperature-stabilized CCD can be synchronously set to zero. This feature offers the possibility to measure single pulses within a pulse chain. Of course other spectral ranges e.g. including the VIS are possible as well.

Stray light and dark signals

Stray light and dark level offsets have a significant influence on the measurement results of UV spectroradiometers employing CCD or CMOS array sensors.

- Stray light incorrectly illuminates pixels thereby producing measurement signals that do not result from the desired wavelength. If stray light is not suitably suppressed, it becomes impossible to separate the LED’s real spectrum from stray light effects. The BTS2048-UV spectroradiometers offer innovative stray light suppression through integrated light traps and optical filters.

- The influence of dark signals results from varying operating temperatures of the measuring instrument and adapted integration times for specific irradiance levels. The dark signal shutter of the BTS2048-UV spectroradiometer is used to measure the dark signal which is used for the dark signal correction of future measurements.

Factory calibrations and ISO/IEC/EN 17025 testing measurements

The measurement laboratory of Gigahertz-Optik offers high quality and traceability of their DCP-UV-LM92 factory calibrations. Factory calibrations are handled in Gigahertz-Optik’s calibration laboratory using the same quality management procedure which applies to NMI accredited test measurements. NMI accredited testing measurements with an ISO/IEC/EN 17025 testing certificate are optionally available.

DCP Test Station complete system with spectroradiometer and SMU

Vektrex TM Spike Save and BTS2048, a powerful combination

DCP Method (IES LM-92-22) Example Measurement of a UV LED

Similar Products

Product Categories