LED Manufacturing and Assembling Measurements

The manufacture of LEDs and LED based products requires specialized measurement technology for the accurate measurement of light intensity, spectral power distribution, color and other quantities. Gigahertz-Optik GmbH offers a comprehensive range of LED light measuring devices, accessories and calibrations. Some example uses of Gigahertz-Optik GmbH products within the field of LED manufacturing and processing follow.

Our sales team will be happy to answer any questions you may have about the measurement during LED production and processing.

+49 (0) 8193 93700-0

LED, Micro LED (µLED) and VCSEL Measurement Systems

From a metrology point of view modern optical measurement systems have to follow this development and make measurements easy whilst offering high accuracy. An ISO 17025 calibration is most important.

Measuring the Effect of Temperature on LED Performance

Good thermal design of LED light sources and luminaires is essential to ensure optimum LED performance with respect to light output and lifetime. LEDs do not radiate significant amounts of heat but within the LED’s semiconductor junction heat is generated which must be dissipated by convection and conduction. The internal quantum efficiency of LEDs decreases as the junction temperature increases. Junction temperature increases as the current through it is increased. Therefore, the operating junction temperature is determined by the drive current, ambient temperature and the efficiency of the heatsink design.

Lighting manufacturers ensure the quality of their products by measuring photometric and colorimetric parameters such as luminous flux, spectral power distribution, colour temperature and colour rendering.

Luminous Flux and Color Measurement of Board Mounted LEDs

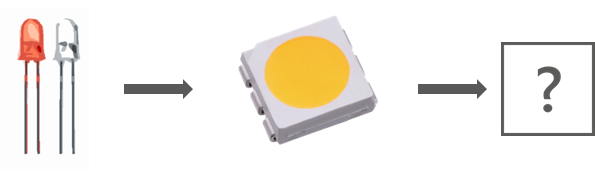

Manufacturers offer LEDs sorted or ‘binned’ according to their Correlated Color Temperatures (CCT), lumen output and forward voltage parameters. For example, standards such as ANSI C78.377-2017 specify the range of chromaticity values recommended for general lighting in terms of ‘bins’ that are defined by a series of chromaticity quadrangles plotted along the black body locus in the CIE 1931 or CIE 1976 color space.

Although this pre-sorting limits tolerance ranges, it does not release the user from metrological quality control. This is mainly due to the fact that the operating parameters used for LED binning do not match those of the end application. The measurement of UV LEDs, VIS LEDs and NIR LEDs on board for quality control can be perfectly done with our measurement equipment.

Spectroradiometer Requirements for LED Binning

Despite the most sophisticated manufacturing technologies employed by the semiconductor industry, light output and colour temperature of LEDs varies from chip to chip. Therefore, binning is employed to maximise yields and to categorise products. Standards such as ANSI C78.377-2017 define tolerance bands or ‘bins’ with respect to chromaticity boundaries. Therefore, without exception, LED binning requires the absolute spectral power distribution of devices to be measured in order to precisely determine the light output and the correlated colour temperature (CCT) of each individual LED. Light output is most commonly measured in terms of luminous flux (lm) although Averaged LED Intensity is also sometimes specified.

Quality Control of LED Spotlight Manufacturing Processes with a Single Measuring Device

The development and manufacture of good quality LED spotlights requires an extensive range of photometric and colorimetric measurements. The investment required for equipping and operating a comprehensive photometric test laboratory can seem prohibitive for the many medium-sized manufacturers offering products in this marketplace. Therefore, the possibility of a universally applicable and compact measuring device for the various measurement tasks is attractive.

DCP Test Station for UV LEDs

UV LED measurements have always been a challenge due to the lower efficiency of the LEDs, lower signals and longer integration times temperature effects are a challenging task. This leads to significant measurement errors. With the DCP (Differential Continuous Pulse) measurement method and answer has been found for this challenge.